Realization of “small, lightweight, and inexpensive products”

Ideal product concept

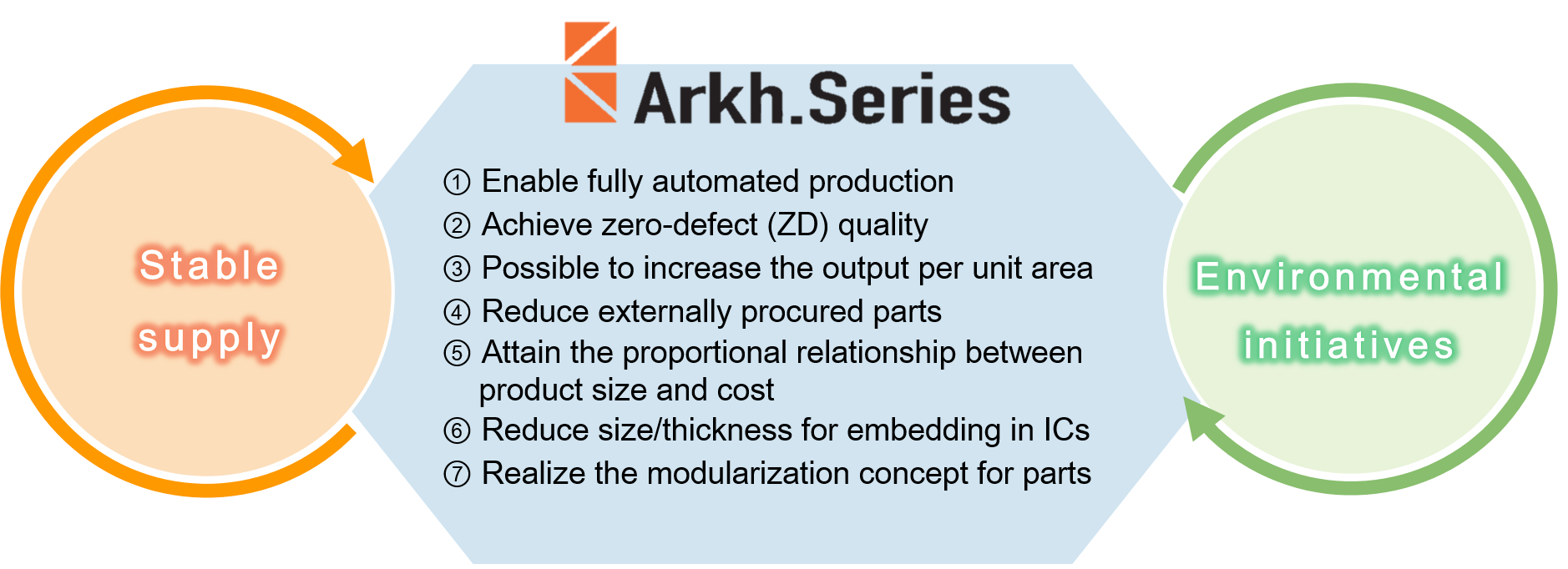

We aim to achieve both “stable supply” and “environmental initiatives” through the Arkh series, which represents our key products.

There are seven key points below for the ideal product concept.

(1) Fully automated production and (2) Achievement of ZD quality

The wafer-level packaging (WLP) method is used for the Arkh series.

Fully automated production, which was difficult to achieve by the 1-by-1 processing method for conventional products, can be realized by the WLP method. In fully automated production, various processes are performed under a vacuum. This eliminates the risk of foreign matter contamination, leading to improved quality and even zero-defect quality.

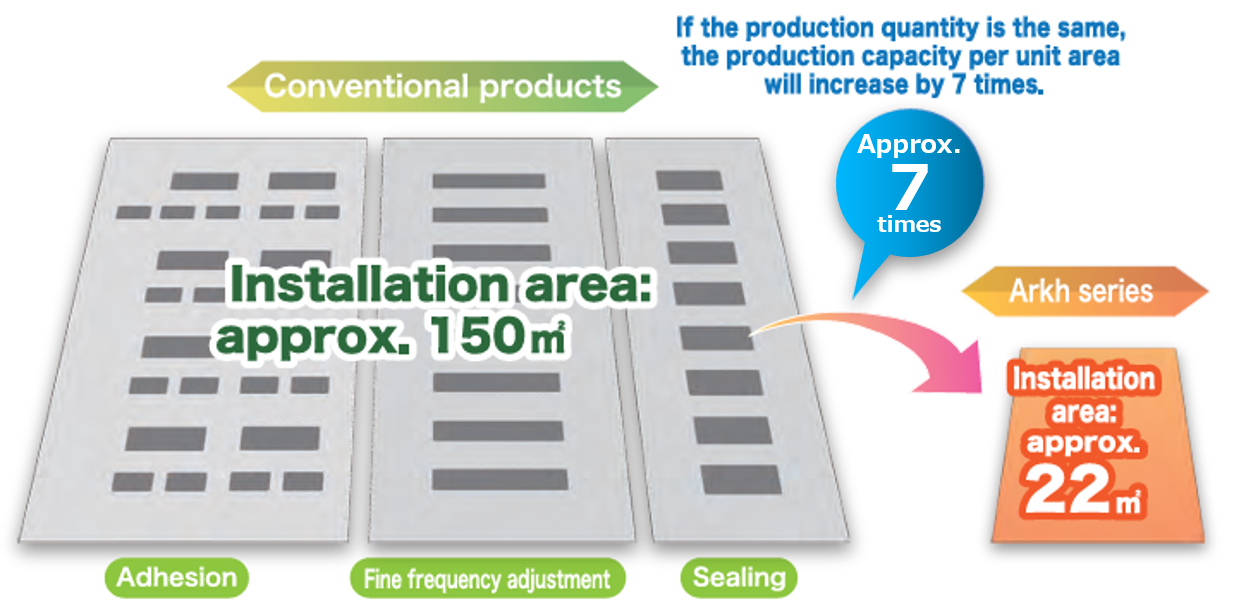

(3) Increase in the output per unit area and environmental initiatives

Compared with the 1-by-1 equipment for conventional products, the production equipment used for the WLP method enables assembly in the form of wafers. This makes it possible to significantly reduce the equipment installation area, including the area required for transfer, increasing the output per unit area by about seven times. This means that auxiliary equipment, including clean rooms, can be reduced to one seventh for the same production volume as that of conventional products. This also leads to reduction of CO2 emissions at plants, making it possible to realize both a stable supply, which is achieved by an increased output, and environmental initiatives.

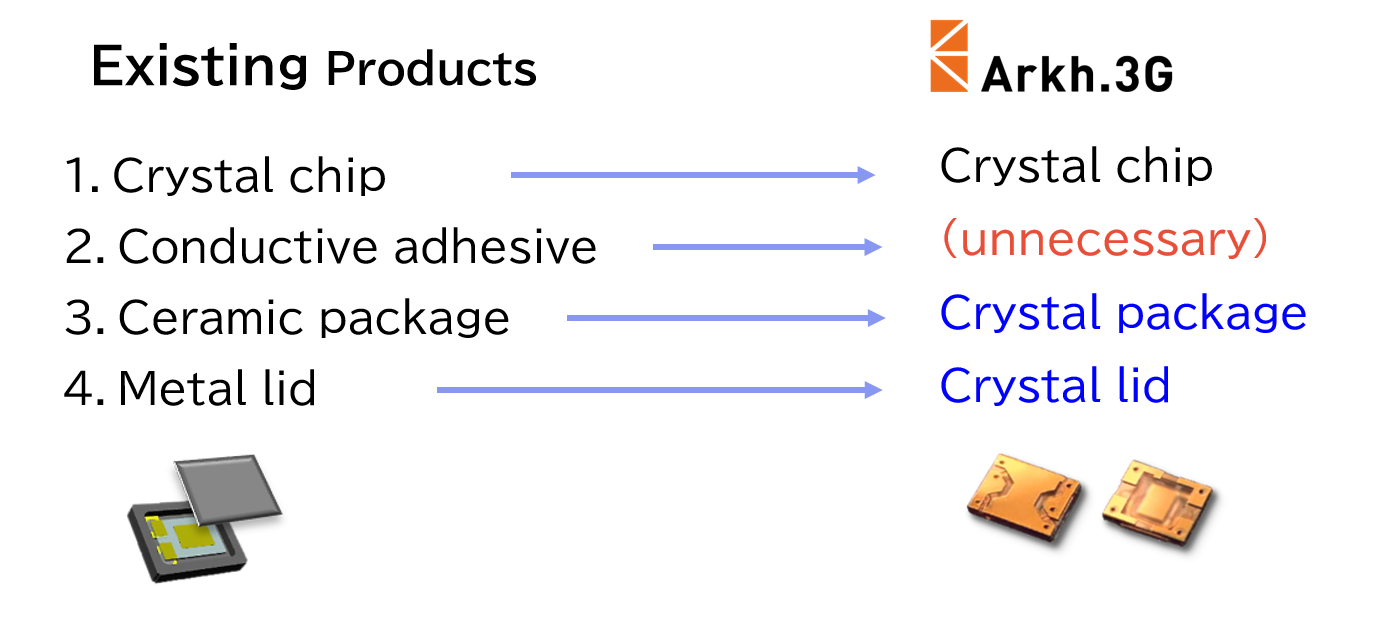

(4) Reduction of externally procured parts

We can procure quartz crystals in-house because we perform integrated production of synthetic quartz crystals from growth to processing.

The Arkh resonators do not use ceramic packages or metallic lids. All the components except for electrode materials are made from quartz crystals. No conductive adhesive is used, either. Thus, externally procured parts can be almost eliminated.

(5) Attainment of the proportional relationship between product size and cost

In terms of the WLP method, the smaller the product size, the greater the number of producible crystal chips from a wafer of the same size. The cost decreases in proportion to the product size. Because wafers are handled as a whole, the difficulty of assembly remains unchanged as long as the wafer size is the same, even if the size of quartz crystal blanks is reduced.

(6) Reduction in size/thickness for embedding in ICs

The Arkh series also supports IC embedding and other high-density surface mounting, including System In Package (SIP). While the thickness of the thinnest crystal resonator among conventional products is 300 μm, the thickness of the Arkh.3G is 130 μm, which is less than half.

In addition to miniaturization, realization of exceptional thinness, which is uncommon in the conventional crystal industry, has made it possible to mount crystal resonators in locations that were previously considered impossible.

(7) Modularization of the Arkh series

The Arkh series can be easily modularized only by mounting an additional part on top almost without changing the structure of crystal resonators. For example, a crystal oscillator can be fabricated only by mounting an IC on top of a crystal resonator.

Pursuit of “small, lightweight, and inexpensive products”

Through the integration of the Arkh series, which was designed based on seven key points for the product concept, with the increase in size of quartz crystal wafers, which is our core technology, we pursue “small, lightweight, and inexpensive products,” which is our ideal, and further enhance our corporate competitiveness.