Reduction of externally procured parts

Component parts of quartz crystal devices and procurement risks

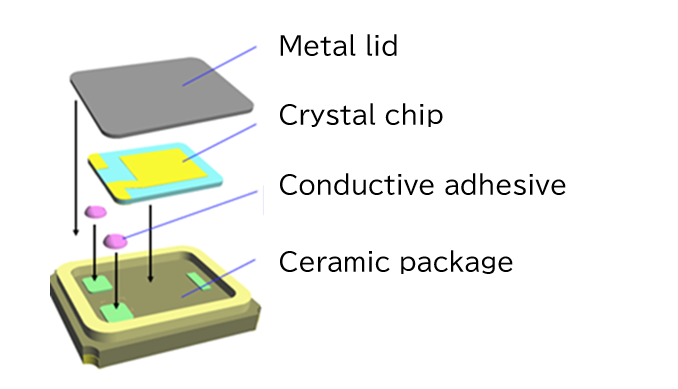

Quartz crystal devices comprise various parts. For example, a quartz crystal resonator is made up of a crystal chip, conductive adhesive, a ceramic package, and a metal lid. For component parts other than crystal chips, we basically procure them from external suppliers. The external procurement ratio is considered to be high.

A high external procurement ratio poses risks in terms of stable supply. For example, it becomes difficult to procure parts in the event of a disruption to the supply chain. To realize stable supply, which we consider a material issue, the component parts must be changed.

Component parts that achieve stable supply

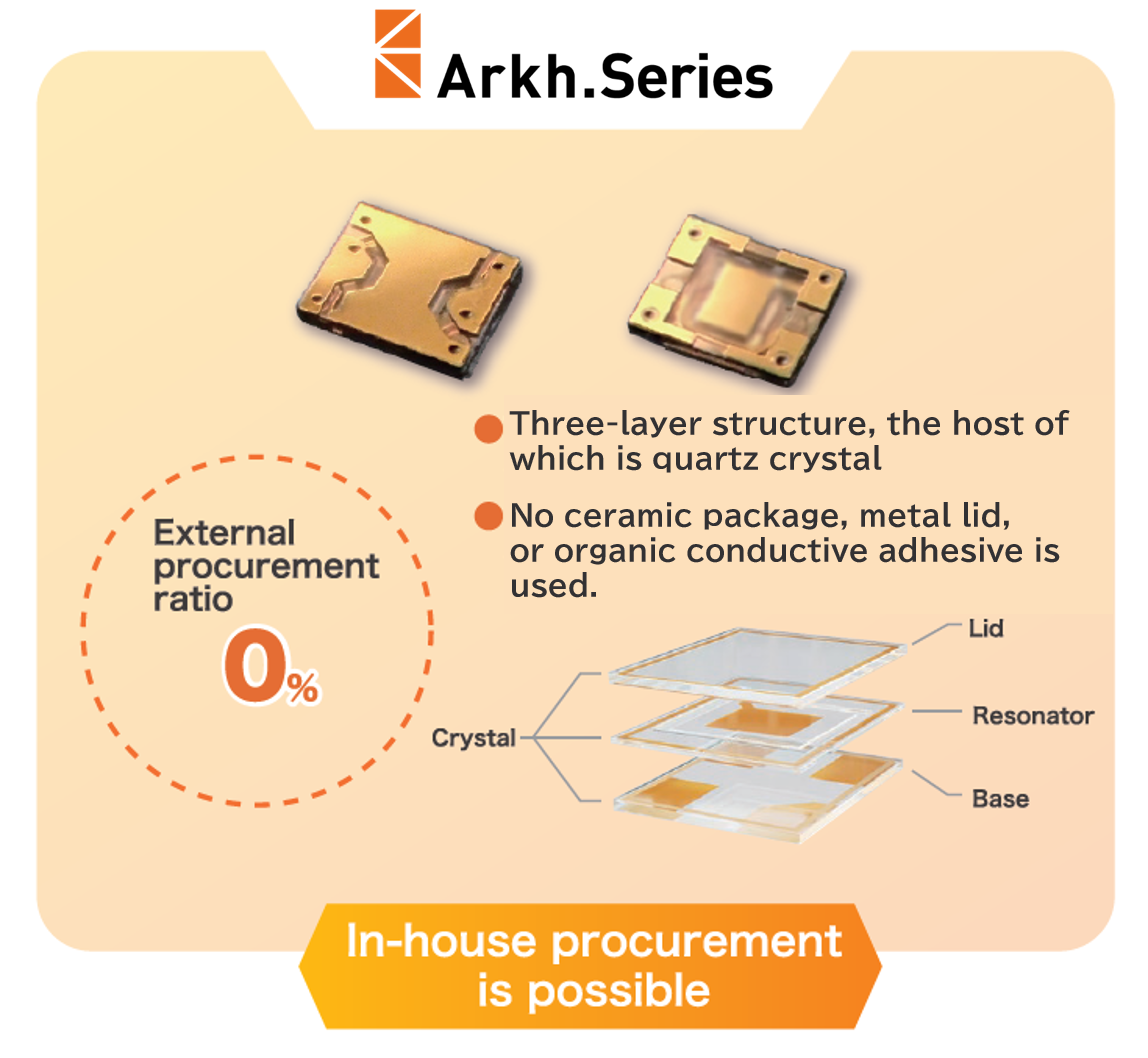

We perform integrated production from the growth to the processing of rough quartz crystals. The external procurement ratio can be reduced if quartz crystals can be used as materials other than crystal chips. As we have explained before, the Arkh series represents our original key products, whose basic structure consists of a three-layered quartz crystal. No ceramic package or metal lid is required, and the quartz crystal element is integrated with part of the package, thereby eliminating the need for conductive adhesives. In this way, the Arkh series almost eliminates the part procurement risks and enables stable supply by thoroughly reviewing the component parts compared to conventional products.

Reduction of environmental impact

Reduction of the external procurement ratio also makes it possible to reduce the environmental impact. For example, the Arkh series does not use conductive adhesives. Thus, unlike conventional products, the Arkh series does not require operation of high-temperature furnaces for drying and curing adhesives. Energy consumption and the equipment footprint can be reduced, leading to energy conservation and lower CO₂ emissions.

The use of quartz crystals for packages and lids realizes wafer level packaging (WLP). Because WLP enables direct processing of quartz crystal wafers, the efficiency of the manufacturing process can be increased, giving an advantage in terms of both supply and the environment.