Fully automated production

Need for fully automated production

To meet ever growing demand, we must not only balance stable supply and environmental initiatives but also cope with manpower shortages attributed to a declining birthrate and an aging population while pursuing the improvement of the quality level. We have been working to attain fully automated production as one of the solutions to fulfill these goals.

For example, if the required quantity doubled, doubling the number of plants, production equipment, and manpower would certainly increase the supply, but the environmental impact would only increase. To balance stable supply and environmental initiatives, it is essential to increase the output with a small number of personnel without expanding the floor space of plants. Accordingly, fully automated production is an indispensable initiative.

Improvement of the quality level

When checking whether products are manufactured properly, the check must be performed by visual inspection if the process is not automated. However, this requires high levels of concentration and experience. Human error is likely to occur. Automation of the process, which relied on checks by visual inspection, by image recognition using sensors and cameras can reduce human error and stably manufacture products of the same quality. Thus far, we have promoted partial automation. We aim to improve the quality level by realizing fully automated production.

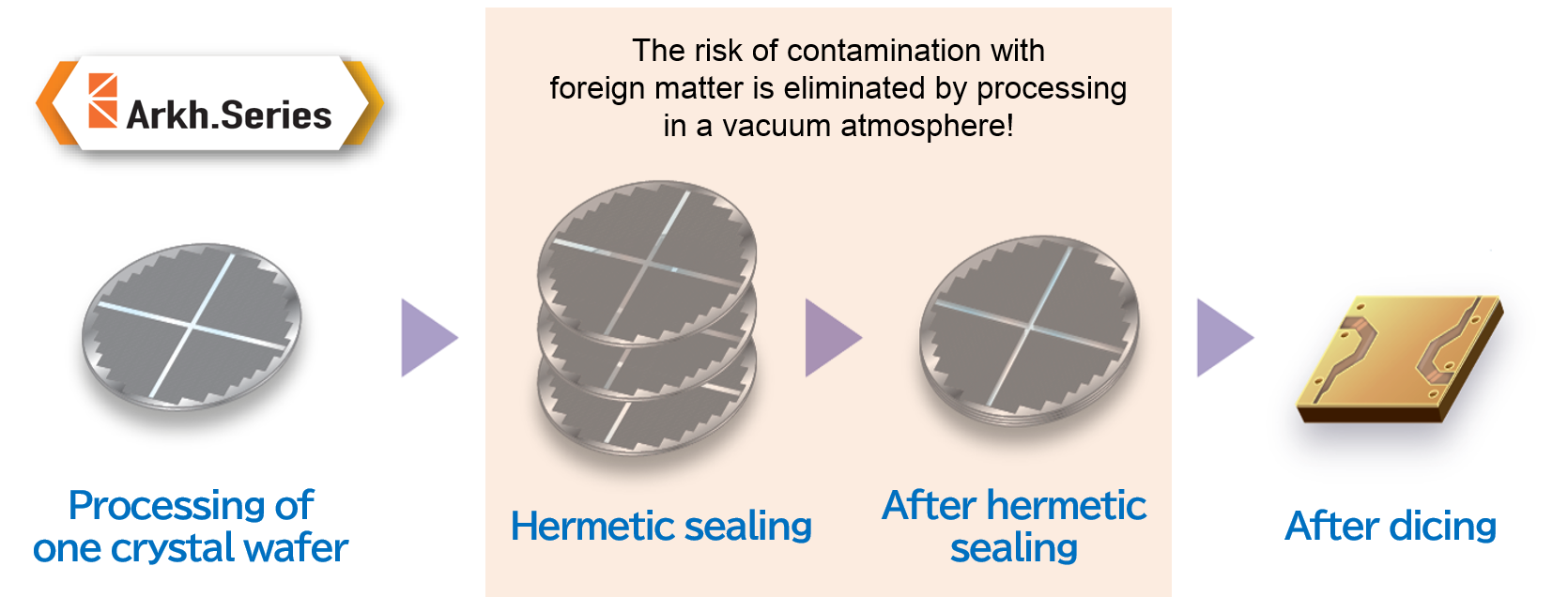

Realization of fully automated production requires both production equipment and product designs that are compatible with such production. The Arkh series, which represents our original key products, adopts wafer-level packaging (WLP) technology that allows three crystal wafers to be bonded together. Because the assembly process is performed in a vacuum atmosphere, the risk of contamination with foreign matter can be eliminated. This is considered a revolution of the manufacturing process to improve the quality of crystal devices.

Revolution of human work

To eliminate manpower shortages attributed to a declining birthrate and an aging population and achieve growth, higher productivity must be attained with a limited number of personnel. This requires changes in the workstyle of workers. Human work will be replaced by fully automated production equipment. Workers will manage the manufacturing flow without touching products being manufactured. Eventually, management of the manufacturing flow will also be automated, and human intervention will only be needed for problems that require manual work.

We have introduced automated transfer robots and started to verify the possibility of transferring products between processes. With the aim of further evolving the human work at our company, we will revolutionize the work to be creative, including creation of new value.

[Automated transfer robot]

In this way, we aim to balance stable supply and environmental initiatives based on fully automated production, improve the quality level, revolutionize the human work, and realize high-quality and environmentally friendly manufacturing.