DAISHINKU develops world’s thinnest* Tuning Fork Crystal Resonator in 1610size, the DST1610AL

DAISHINKU CORP. (President: Sohei Hasegawa) announces development and release of world’s thinnest* tuning fork crystal resonator in 1610 size. Many digital devices use a 32.768 kHz tuning fork crystal oscillator as an electronic component to provide a source clock frequency. Recent trends in electronic equipment toward smaller size and lower profile, but with higher performance and functionality, demand their components to follow the same trends. Following our presentation of the subminiature tuning fork crystal oscillator DST1610A at CEATEC Japan 2013 held some days ago, we have made it thinner and achieved a maximum product height of 0.35 mm to be embedded into smart cards. Smart cards have become an everyday item, typically used for electronic money. The amount of information stored on a smart card is substantially larger than on a conventional magnetic stripe card. Accordingly, it has become necessary to enhance smart card security. Development of a card capable of generating one-time passwords is under way. Such cards need to have a built-in tuning fork crystal oscillator to provide an accurate source clock frequency. However, it is difficult to embed a conventional tuning fork crystal oscillator into a smart card whose thickness must be 0.76 mm, as required in the standard specifications for smart cards. The challenge for us has been to reduce the height of crystal oscillators to as ultrathin as 0.35 mm at maximum. Generally, when downsized, a tuning fork crystal oscillator noticeably degrades in electrical characteristics since its series resistance increases. Moreover, in element mounting, the conventional use of electrically conductive adhesive is subject to design limitations if the aim is to make the product smaller and thinner. To solve these problems, we have refined the element design (patented) first employed in the existing model DST210A. New element design (patented) provides a necessary distance between oscillating and base sections. The results are reduced oscillation leaks to the base section and reduced increases in series resistance. The FCB method used to mount the element on the package provides stability in mounting-position accuracy, an important factor in making the product low profile. Our manufacturing process has also been refined to enable higher-accuracy processing while using our existing production equipment. Since the tuning fork element mounted in the DST1610AL is designed to be subminiature, heat generated in the manufacturing process causes the crystal element to expand and contract and affects the product yield. Having established an engineering method to reduce the heat, we have improved the processing accuracy. Furthermore, in terms of characteristics, the DST1610AL is equivalent in performance and reliability to the existing model DST210A.

* Source: survey by DAISHINKU CORP. valid as of November 4, 2013

- [Features]

-

- Ultra miniature SMD tuning fork crystal resonator (1.6×1.0×0.35mm max.)

- A ceramic package with metal lid providing high precision reliability.

- A ceramic package with metal lid providing high precision reliability.

- Pb Free

- RoHS Compliant

- [Main applications]

- Smart card, Mobile communications and Consumer devices

- [ Mass Production date ]

- Feb., 2014

- [Manufacturing Capacity ]

- 2 million/month

- [Sample Price]

- 500 yen Samples are available now

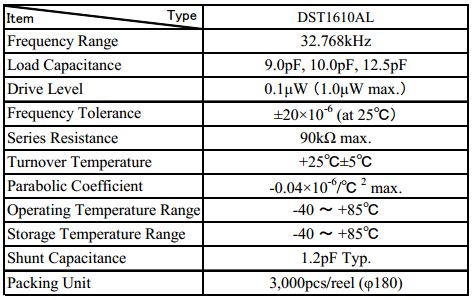

- [Electrical specification]

Consult our sales representative for other specifications.

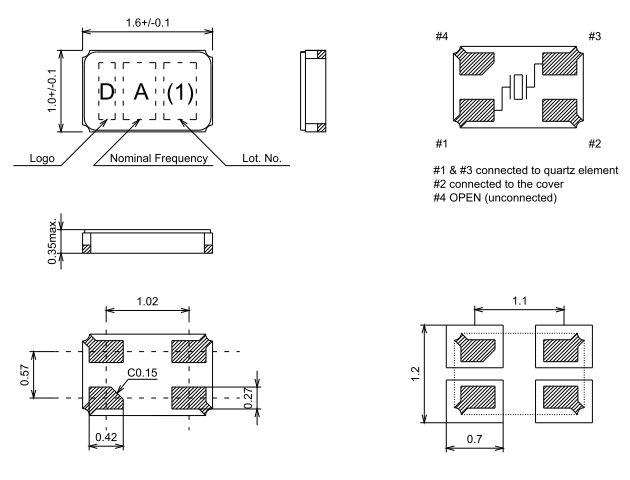

- [Dimensions]

- Financial Results Supplementary Materials for the First Three Quarters Ended December 31, 2025 (FY2026 Q3)

- Summary of Financial Results for the First Three Quarters Ended December 31, 2025

- Uploaded "KDS New Wave" [Story-22] Advantages in the Manufacture of the Arkh.2G

- Transcript of the second quarter financial results briefing for the first half ended September 30, 2025 (FY2026 Q2)

- Financial Results Briefing for the First Half Ended September 30, 2025 (FY2026 Q2)